5 Tips for Organizing a Warehouse of Spare Parts

Looking for warehouse management best practices and recommendations to make the most of your auto parts inventory? These five ideas inspire you to reduce shortage and keep your stock moving.

Table of Contents

1. Watch Your Inventory Like a Good Parent: Know Where Parts Go

2. Set Up a Central Storage Area: Consolidate and Label

3. Keep Records of Your Parts: Use Technology, Not Pen and Paper

4. Store Your Parts Properly: Clean and Maintain the Storage Space

5. Find What’s Missing: Do a Regular Check of Your Spare Parts Stock

6. Final Thoughts

It’s no surprise that having a warehouse of vehicle spare parts and accessories at the disposal of an auto repair shop makes offering services and repairing jobs more manageable and much less time-consuming. What may surprise you is the amount of work and attention it takes to maintain a prosperous and orderly stock. Here are five warehouse management tips to help you organize your spare parts and optimize their storage.

1. Watch Your Inventory Like a Good Parent: Know Where Parts Go

Having a great understanding of where each item belongs can help you find the correct ones and do so quickly. When auto parts linger in a space that isn't theirs, it's hard to find their appropriate homes. Here are some things you can do to make sure that inventory is not missed or misplaced:

- An excellent way to organize a spare parts warehouse is by piece count, with the most commonly needed parts being in the front.

- Let your employees know what inventory is in a warehouse by having it visible — physically in the room and virtually in your database.

- Create a system to know where the part is — hanging from the ceiling, for example, or labeled with a date.

- Maintain a calendar of all future purchase orders with the due dates and a list of all known suppliers with contact information to avoid running out of necessary items.

- Don't throw out unused parts — they may not be needed right now, but who knows what will happen. Treat your inventory like a bank of resources you can use to get you back up and running when the situation changes.

2. Set Up a Central Storage Area: Consolidate and Label

Collecting and storing your spare parts is a big project, but it's important to divide it into smaller tasks and do them step-by-step.

Step 1. Audit your current storage and how often old parts get stashed in random places and forgotten about.

Step 2. If need be, find a new space to store them, and measure it out for how many shelves and bins you need. This can be a garage, a shed, a basement, or a room in your car repair shop building.

Step 3. Collect all the parts you have. Put them on shelves or in bins, and be sure you leave enough room for new products. You'll want to keep everyday items in one spot, so you can quickly find and access them easily.

Step 4. Sort your inventory by function and manufacturer. E.g., separate those for cars, boats, and motorcycles.

Step 5. Allocate space for each function. You may want to designate a section for your heaviest pieces, your lightest items, and different wires and fasteners.

Step 6. Identify what spare parts you have and what can go wrong with them. This way, you can find the right tools to fix the issues.

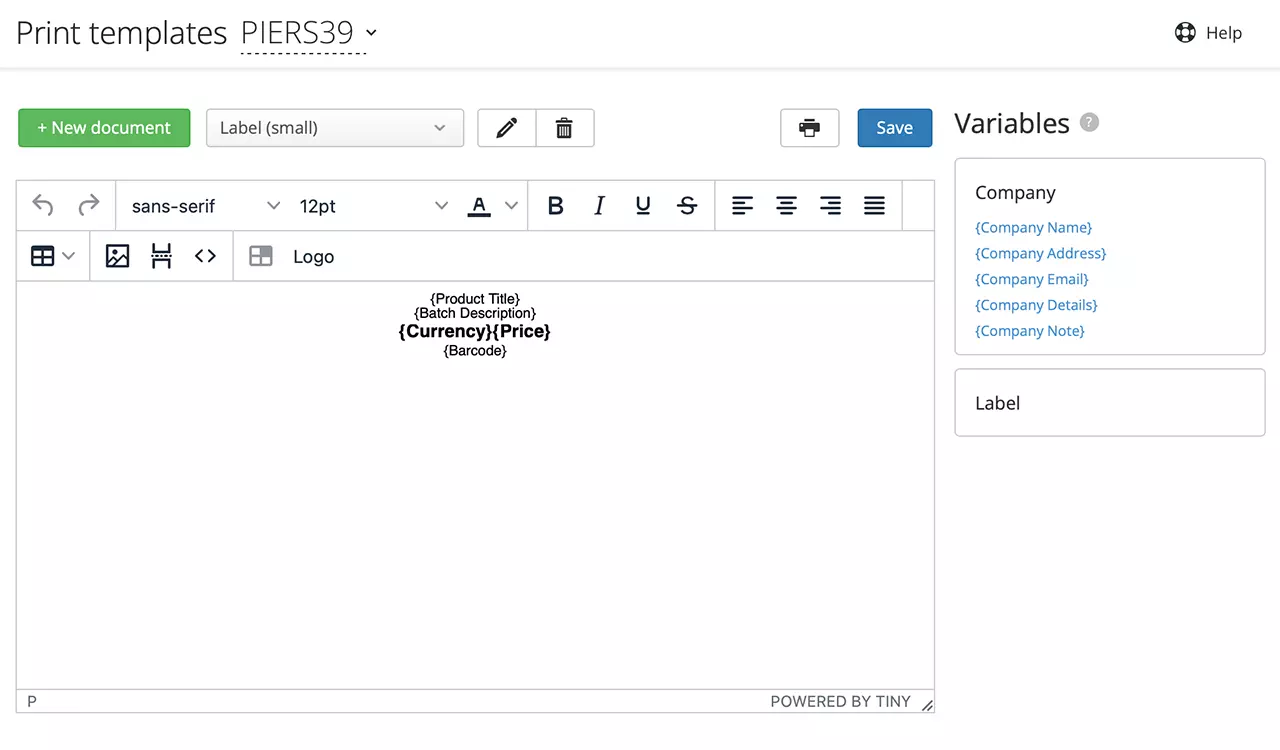

Step 7. Label goods and containers to ensure you don’t have to search boxes for the needed parts. To speed up the process, use a label maker. For example, in RemOnline, you can set up label templates and print them out to organize your spare parts inventory.

Configuration of a print template of labels in RemOnline

Idea: Implement a bin location system for more accurate storage of small items. This can be really helpful when it comes to consolidating inventory.

3. Keep Records of Your Parts: Use Technology, Not Pen and Paper

It is crucial to keep inventory records up-to-date to have what you need when you need it. But managing the warehouse operations manually will be nearly impossible, so don’t waste your valuable time and resources.

To increase employee efficiency and simplify your warehouse operations, consider implementing a part management software solution to handle recurring tasks like postings, transfers, and write-offs. Ensure you’ve got the proper inventory control, scanning technology, and multi-location management system to scale your business.

In the CRM RemOnline for auto repair shops, you’ll be able to manage every area of your business — from customers, work orders, and sales to warehousing and inventory.

4. Store Your Parts Properly: Clean and Maintain the Storage Space

If your warehouse is cluttered, it’ll be hard for your people to work efficiently. Warehouse chaos can lead to confusion and stock-outs of the most popular products. The more messed up your warehouse gets, the more time you’ll spend cleaning it up and organizing infrastructures, like shelving and tools. Storage of parts inventories is never cheap, so the best course of action is to not have too much stuff in there in the first place.

Let’s have a look at the practices you can do to avoid clutter:

- Clean up the storage area and replace tags and stickers regularly.

- Remove any piece that is no longer in use. Make sure to keep any manuals in case you’ll need them in the future.

- Keep things organized in their own categories, such as nuts and bolts, valves, and gaskets.

- Protect the spare parts by keeping them organized and in a dry area to prevent corrosion.

- Ensure to avoid storing them at a pace where they will be exposed to sunlight.

5. Find What’s Missing: Do a Regular Check of Your Spare Parts Stock

Performing inventory reconciliations regularly is a great way to ensure your stock is not a mess and you’re not wasting time and space stocking unnecessary parts. You can take stock of everything you have and create a list that coordinates the part number, quantity, and location of each item to identify goods available in stock. Once you’ve reconciled and updated your data, you can make wiser decisions about which parts to keep and which to discard or whether to stock your warehouse with more items.

In RemOnline, you’ll have four stocktaking methods to choose from: with a barcode reader, by importing/exporting a file of goods, using paper sheets, or by uploading a product list.

Final Thoughts

A well-organized inventory is a necessity for any auto shop. Your garage can complete customer repairs on time with a proper part management system. Technology, such as a software solution, will help you cut down on time and the number of mistakes you make when stocking your warehouse. As a business owner, you may want to invest in a barcode reader and use a labeling system to speed up the picking and stocktaking processes.