The Best Ways To Keep Track Of Work Orders In Small Service Business

Small business owners know that work order management is critical to keeping their businesses running smoothly. But what are the best ways to manage work requests? This guide will help you get started with organizing your work orders with maximum efficiency.

Table of Contents

The Basics of Work Order Management

Why Is It Important to Manage Work Orders?

6 Tips For Keeping Track of Your Work Orders

Final Thoughts

In business, work order management software is the process of creating, assigning, and tracking work orders. It helps ensure that work is completed in a timely and efficient manner. By creating work orders and assigning them to specific employees, you can make sure that each task is given the attention it deserves. Work orders can also help track the progress of each task so you can ensure that it is completed on time.

The Basics of Work Order Management

Keeping track of work orders is a key process in small service businesses as it helps organize work requests, schedule and assign resources to tasks, and control the progress of work.

What is a Work Order?

Work orders are requests for specific services or products to be delivered or manufactured, typically from a customer to a supplier. Work orders can be for routine maintenance/repair or for a specific project. As a document, a work order requests or authorizes the provision of a specific service. You can generate work orders for a variety of services, including, but not limited to, repairs, installations, and alterations.

There are a few things to consider when creating work orders:

- Who is the customer?

- What is the work to be done?

- What are the specifications?

- What are the delivery dates?

- What are the costs?

- Who will be performing the work?

- How will the work be tracked and monitored?

Creating work orders can seem daunting but it is important to remember that the more you do it, the easier it becomes. In addition, there are many solutions with templates and scheduling management tools out there that can help you streamline your record-keeping.

The Work Order Process

Here's how to process a work order:

- Include as much information as possible on the work order. This will ensure that the work is done to your specifications. Then, check whether all of the information is correct

- Assign the work order to the appropriate technician or team

- Notify the person or department that the work order has been assigned to them (via messengers or email notifications)

- Monitor the progress of the work order and provide updates as necessary

- Close the work order when it is completed

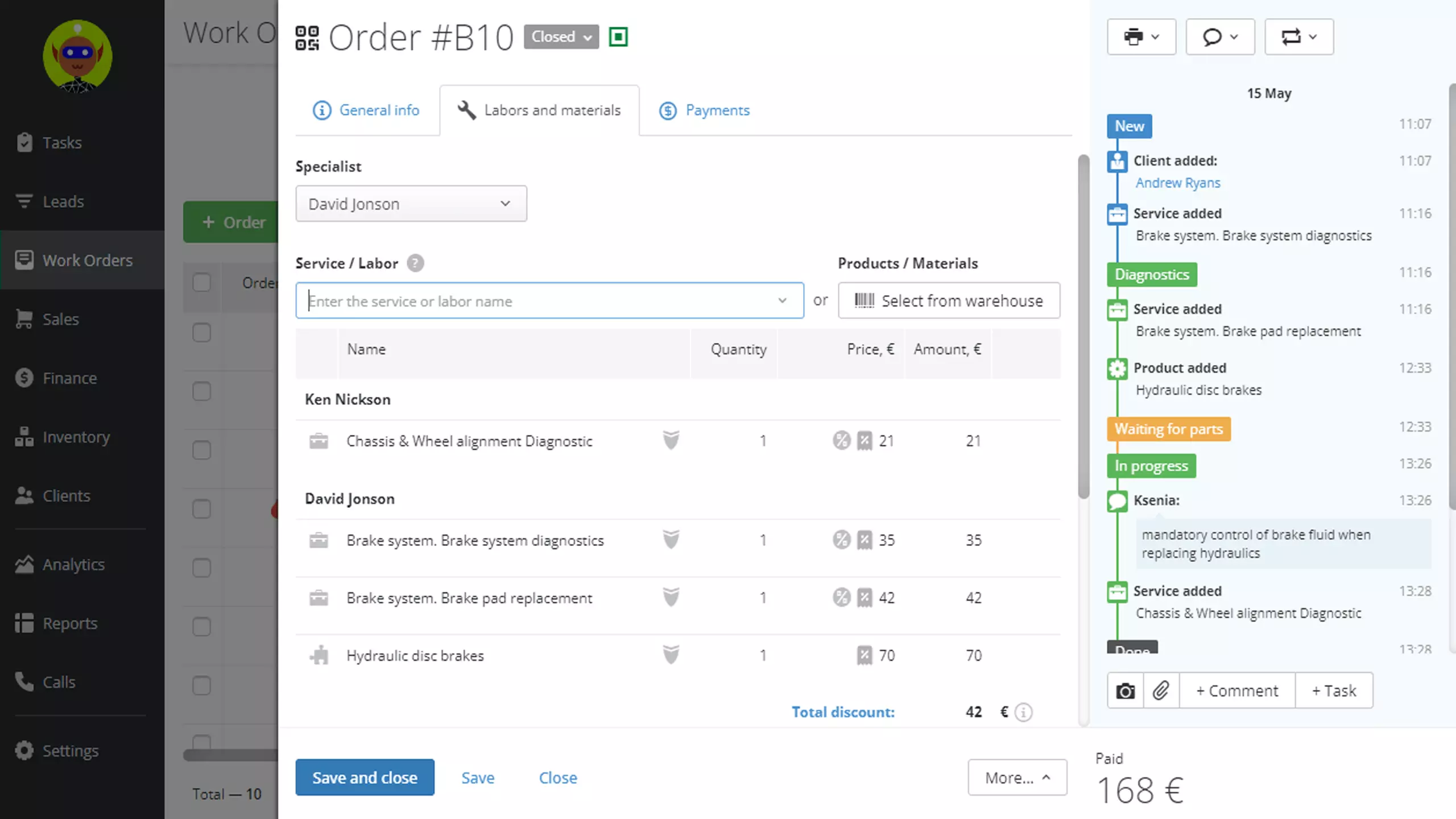

How to Close Out a Work Order

In order to properly close out a work order, you'll need to take a few final steps. First, make sure that all the work that was done is properly documented: the services provided are recorded, the correct parts were used, and the work was done to the customer's satisfaction. Once the documentation is complete, you'll need to either submit the work order to your supervisor for approval or change the work order status according to your repair process workflow.

Why Is It Important to Manage Work Orders?

The work order helps to control what work has been completed, the work that is currently in progress, and what is scheduled for the future. This is also a helpful tool for tracking the costs associated with each job. By creating work orders for each service request and keeping track of the materials used and the hours worked, you can more easily track your expenses on the actual execution and make sure you are charging enough for your services. In the long run, you will know whether the business is making a profit on each job and whether the customer is getting what they expect for their money.

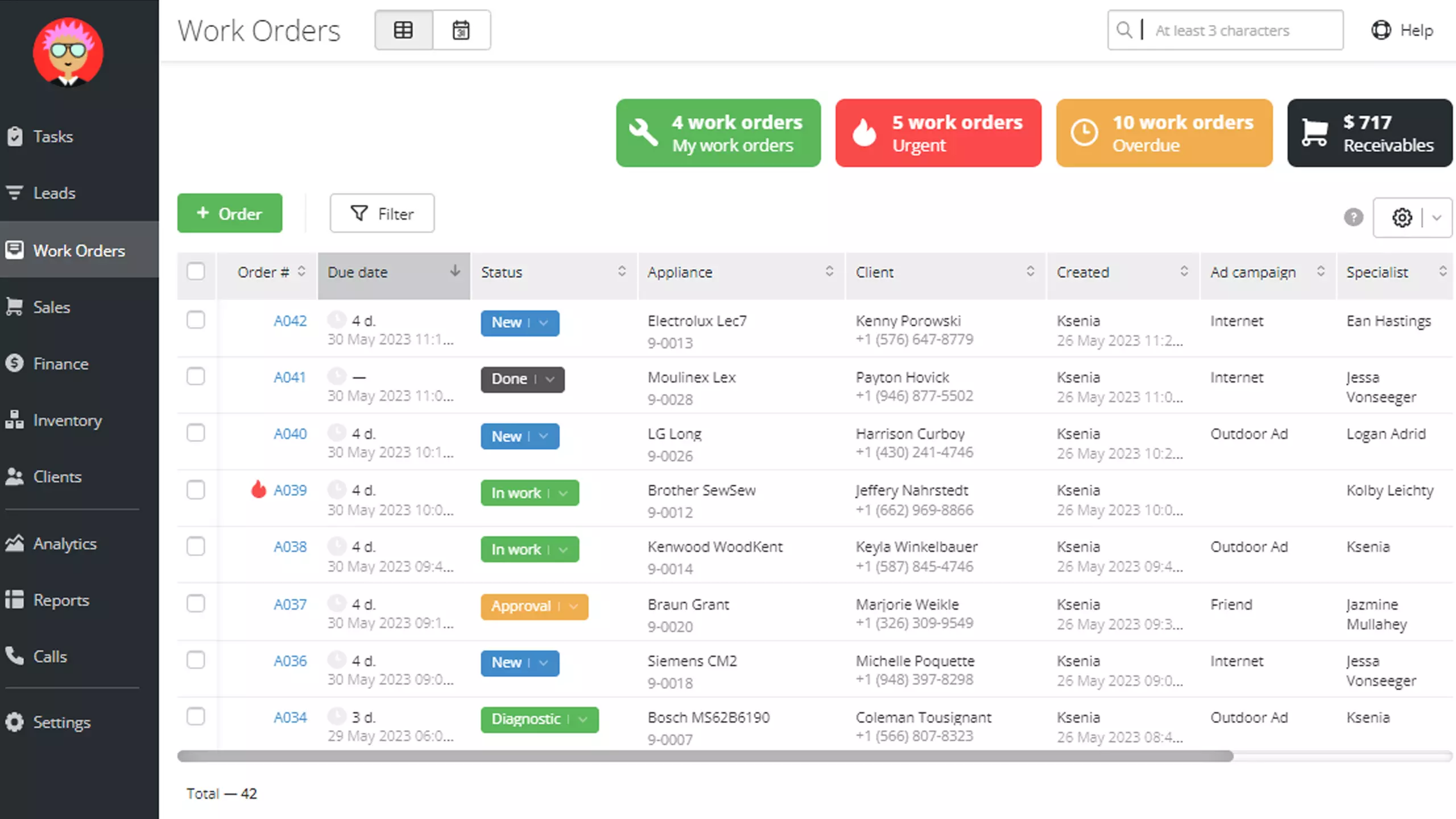

How work orders are displayed in RemOnline

6 Tips For Keeping Track of Your Work Orders

Tip 1. Use a software solution that is specifically designed for the electronic tracking of the work that has been completed. This can help you follow the progress and ensure that nothing falls through the cracks. Make sure that you have a system for assigning work orders to specific employees as well as detailed instructions on work order processing so everyone is aware of their responsibilities and the work is being completed in a timely manner.

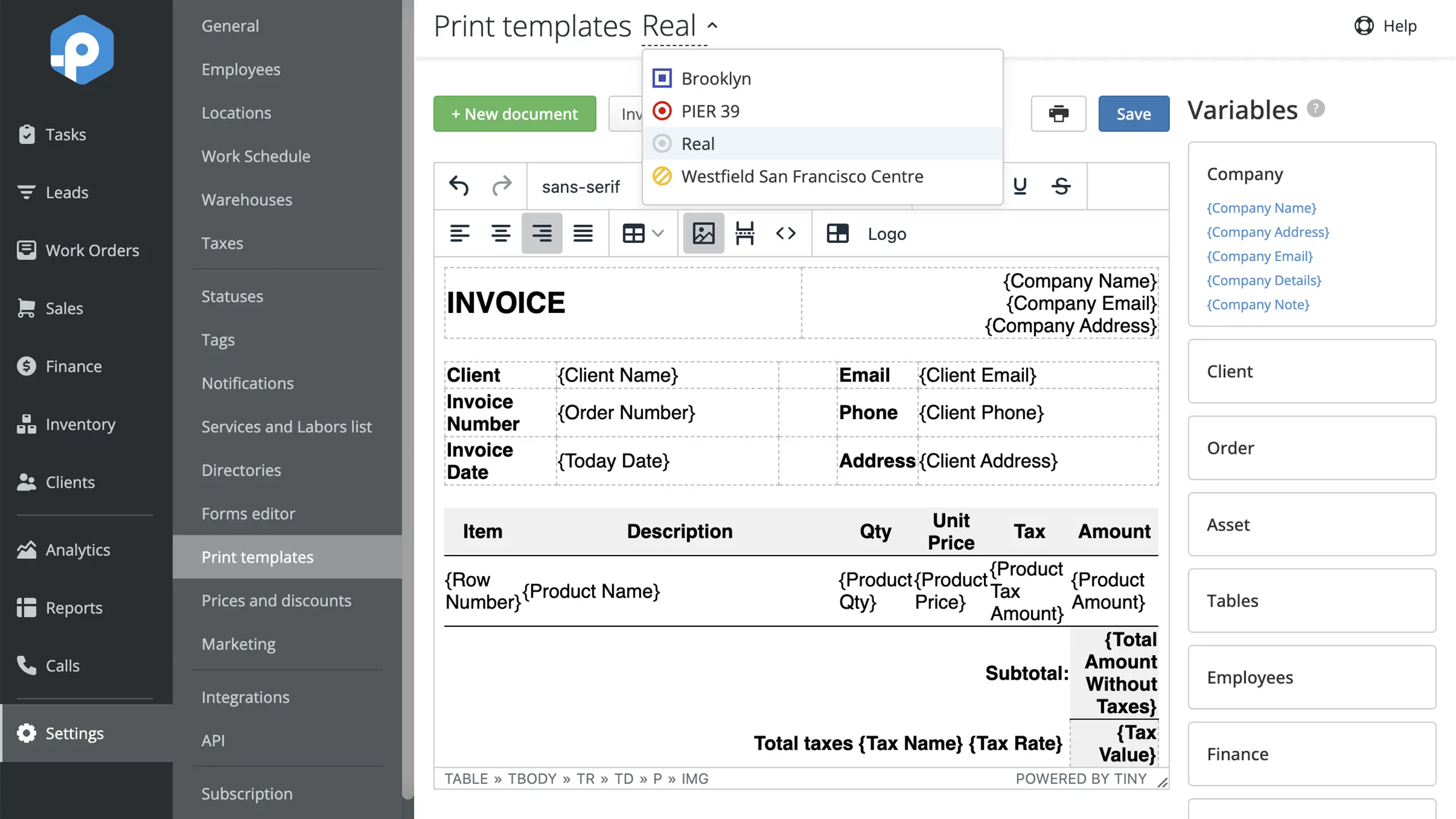

Tip 2. Create templates for common documents you need to generate when processing work orders. E.g., with the intuitive template editor in RemOnline, you can edit custom fields and enable auto-fill in all standard documents like quotes and invoices. This way, variable data stored in your account will be already there when you generate a document from work orders or sales. Your employees will no longer have to enter client, product, or work order information manually.

Screenshot of the Document Template Editor in RemOnline

Tip 3. Monitor the progress of the work, not just the result — to avoid missed deadlines and angry clients you should track the entire workflow process, from requests to completion. This way, you will be able to spot issues in advance and solve them before the main deadline of the work order.

For example, in the work order management software RemOnline, you can control not only deadlines but also each stage of the work order processing using statuses. You just configure the rules for moving from one status to another to build different workflows for different work order types. Additionally, it is possible to set up status time limits for each status so you will see where the process gets delayed.

Work Order Overview in RemOnline

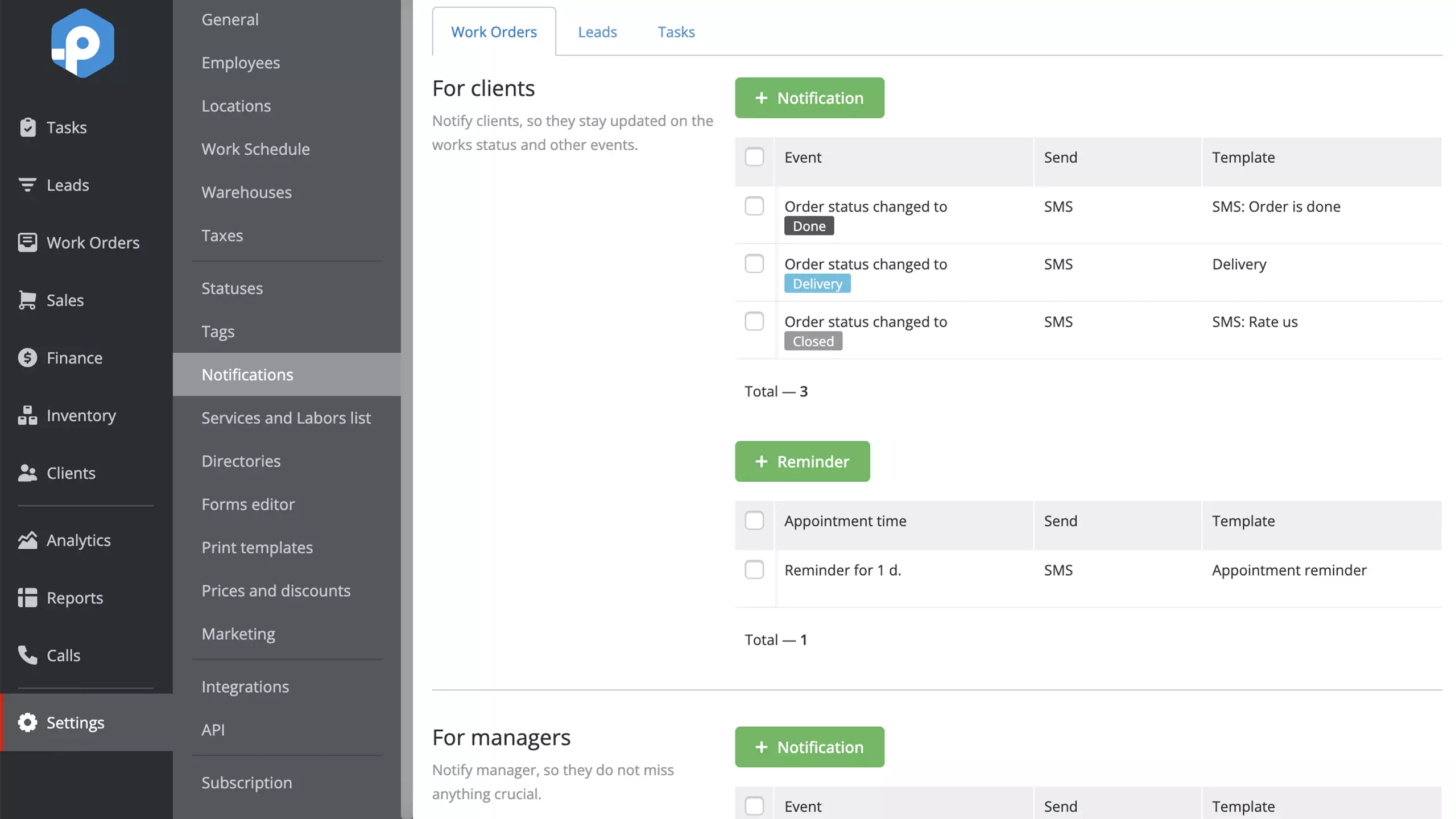

Tip 4. It happens that after a work order has been placed, some changes in requirements or additional requests from customers may occur. Keeping your employees up-to-date is essential to maintaining a productive and organized work environment. In RemOnline, for example, you can set up automatic notifications to employees via SMS or email when there are changes in their work orders or when they are assigned a new task.

Tip 5. Make your customers feel they are having control over the situation by letting them track their work order statuses throughout the entire process. This will calm and give confidence that their work order is really being worked on. In RemOnline, customers can track their work orders with automatic notifications of status changes.

Setting up automatic alerts in RemOnline

Tip 6. Follow up with your customers to ensure that they are happy with the work that has been done so they’ll be more likely to use your services in the future. You can also ask them to review your services on a site like Yelp or Google. This can help other potential customers learn about your business and decide if they want to use your services.

In RemOnline, it’s easy to send a review request to your client after a work order is completed. You just create a template with a message and a variable with a link for the client to the review form. The program will use this template to send out automatic requests via email or SMS after the work order has been closed.

Ready to automate work order processing in your company? Sign up now to use RemOnline free for 7 days.

Final Thoughts

The work order management process is an essential part of running a successful small service business. It can help you keep track of what work needs to be done, when it needs to be done, and who is responsible for doing it. The most effective way to manage work orders is using quality management software where you can access detailed information about each work order in seconds, such as the specific tasks that were completed, the amount of time it took to complete the work, and the cost of the materials used. You can also track the progress of each work order, assign tasks to different employees, and follow up with your customers after the completion of a work order.